-

Capability

-

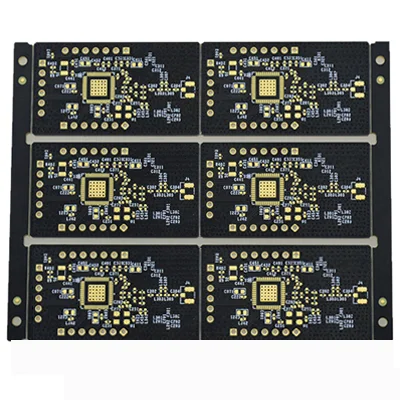

FR4 PCB Capabilities

| ltem | Capability |

|---|---|

| Material | FR-4 Standard Tg 140°C, FR4-High Tg 170°C |

| Min. Track/Spacing | For External layers: 4oz Cu 10mil/13mil, 5oz Cu 12mil/15mil, 6oz Cu 15mil/15mil For Internal layers: 4oz Cu 8mil/8mil, 5oz Cu 10mil/10mil, 6oz Cu 12mil/12mil |

| Min. Hole Size | 0.15 ~ 0.3mm |

| Max Outer Layer Copper Weight (Finished) | 12oz |

| Max Inner Layer Copper Weight | 12oz |

| Board Thickness | 0.6-6mm |

| Solder Mask | HASL lead-free, Immersion gold, OSP, Hard Gold, Immersion Silver, Enepig |

| Solder Mask | HASL lead-free, Immersion gold, OSP, Hard Gold, Immersion Silver, Enepig |

| Silkscreen | White, Black |

| Via Process | Tenting Vias, Plugged Vias, Vias not covered |

| Testing | Fly Probe Testing (Free) and A.O.I. testing |

| Build time | 5-15 days |

| Lead time | 2-3 days |

FR4 PCBs, fabricated from Flame Retardant 4, are the most commonly used type of printed circuit boards in electronics. These boards offer numerous advantages that make them a popular choice for various applications.

Advantages of FR4 PCBs:

- Affordability: FR4 PCBs are cost-effective due to their widespread use and availability of FR4 materials. This makes them a practical choice for both prototyping and mass production.

- Good Electrical Insulation: FR4 material possesses excellent electrical insulation properties, which helps prevent signal interference and ensures the integrity of the circuit.

- Flame Retardancy: FR4 material is designed to be flame-retardant, reducing the risk of fire propagation in case of a short circuit or other electrical faults. This is crucial for safety in electronic devices.

- Mechanical Durability: FR4 PCBs have good mechanical strength and can withstand mechanical stress, making them suitable for applications where the board might experience physical strain.

- High Temperature Resistance: FR4 PCBs can handle relatively high operating temperatures without significant loss of performance, making them suitable for a wide range of electronic devices.