-

Capability

-

12 Layer PCB Stackup Capability

| ltem | Capability |

|---|---|

| Quality Grade | Standard IPC 2 and IPC 3 |

| Number of Layers | 2 – 40layers |

| Order Quantity | 1pc – 1Million+pcs |

| Build Time | 24H – 4weeks |

| Material | S1150G, S1165, S1000-2 |

| Board Size | Min 5*5mm | Max 500*650mm |

| Board Thickness | 0.4mm – 6.5mm |

| Copper Weight (Finished) | 0.5oz – 10.0oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Solder Mask Color | White, Black, Yellow |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 6mil |

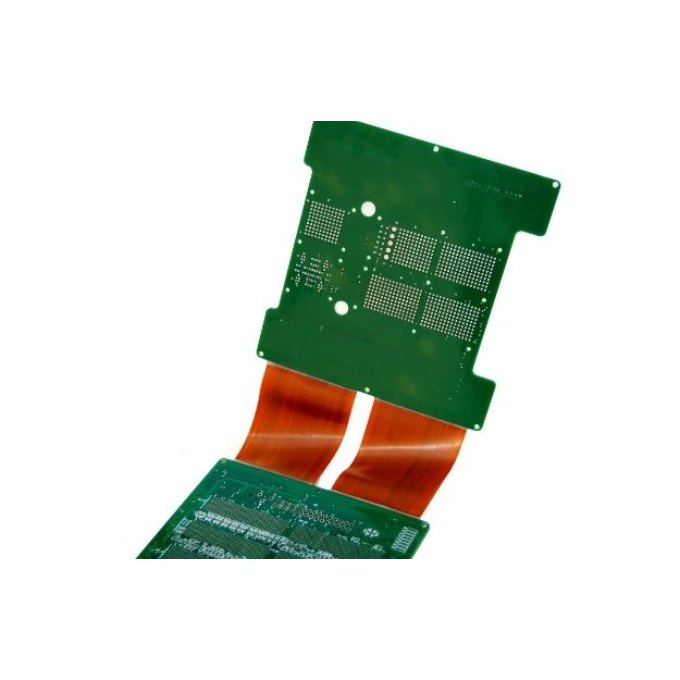

12-Layer PCB Stackup: Superior Multilayer Circuitry

The 12-Layer PCB Stackup offered by us presents a remarkable solution for intricate electronic designs requiring advanced functionality. With a total of twelve layers meticulously arranged, this multilayer circuit board provides exceptional capabilities for complex applications.

Key Features:

- Layer Diversity: Our 12-layer stackup facilitates intricate designs by allowing multiple layers of conductive pathways, providing ample space for routing signals and power distribution.

- Enhanced Signal Integrity: The carefully engineered layer arrangement minimizes signal interference, ensuring optimal signal integrity even in high-frequency applications.

- Power Distribution Efficiency: With dedicated power and ground planes, this stackup optimizes power distribution, reducing noise and ensuring stable performance.

- High-Density Components: The 12-layer stackup accommodates densely packed components, enabling the creation of compact and efficient electronic systems.

- EMI Shielding: The multiple layers aid in electromagnetic interference (EMI) shielding, enhancing the overall electromagnetic compatibility of the PCB.

- Advanced Applications: Ideal for applications demanding intricate circuitry, such as advanced communication systems, high-speed data transfer, and complex industrial control systems.

- Reliability: Crafted with precision and manufactured under stringent quality control, our 12-layer PCB stackup is designed to meet the demands of mission-critical applications.

Whether it’s the intricacies of high-speed data transmission or the demands of advanced industrial automation, our 12-layer PCB stackup offers the foundation for innovative electronic solutions. With our commitment to excellence and cutting-edge manufacturing processes, you can trust in the reliability and performance of our multilayer circuit boards