Vehicle Electronics

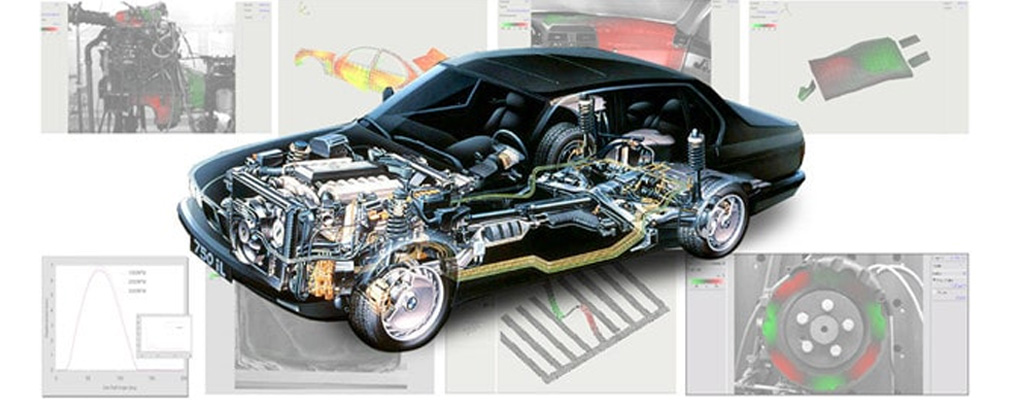

Printed Circuit Boards (PCBs) have revolutionized the way electronic components are connected in a variety of devices, and vehicle electronics are no exception. The use of PCBs in vehicle electronics has increased the reliability and performance of various automotive applications, making vehicles safer, smarter, and more efficient. What are the applications of PCB in Vehicle Electronics?

1. Engine Management Systems

Engine Management Systems (EMS) are the heart of modern vehicles, controlling everything from fuel injection to exhaust emissions. PCBs are essential components of EMS, as they enable the integration of microcontrollers, sensors, and other electronic components into a single system. By using PCBs, automotive engineers can design more compact and efficient EMS, which consume less power and generate less heat.

2. Infotainment Systems

Infotainment systems have become an essential part of modern vehicles, providing drivers and passengers with access to a range of features, such as GPS navigation, audio, and video playback, and communication systems. PCBs are used extensively in infotainment systems, enabling the integration of various electronic components, such as touchscreens, speakers, microphones, and cameras. By using PCBs, automotive manufacturers can create more advanced and user-friendly infotainment systems, which enhance the driving experience and provide greater convenience.

3. Advanced Driver Assistance Systems

Advanced Driver Assistance Systems (ADAS) are becoming increasingly common in modern vehicles, providing drivers with an array of features, such as collision avoidance, lane departure warnings, and automatic emergency braking. PCBs are essential components of ADAS, as they enable the integration of sensors, microcontrollers, and other electronic components into a single system. By using PCBs, automotive engineers can design more sophisticated and accurate ADAS, which can help prevent accidents and save lives.

4. Battery Management Systems

Battery Management Systems (BMS) are critical components of electric vehicles, controlling the charging and discharging of the battery, as well as monitoring its health and safety. PCBs are used extensively in BMS, enabling the integration of microcontrollers, sensors, and other electronic components into a single system. By using PCBs, automotive manufacturers can design more efficient and reliable BMS, which can help extend the lifespan of the battery and improve the safety of electric vehicles.

5. Lighting Systems

Lighting systems are essential components of vehicles, providing illumination for the driver and other road users, as well as enhancing the vehicle’s visibility. PCBs are used extensively in lighting systems, enabling the integration of LED lights, sensors, and other electronic components into a single system. By using PCBs, automotive engineers can design more efficient and versatile lighting systems, which can help reduce energy consumption and enhance the aesthetics of the vehicle.

In conclusion, PCBs have revolutionized the way electronic components are connected in a variety of devices, including vehicle electronics. By using PCBs, automotive engineers can design more compact, efficient, and reliable systems, which enhance the performance and safety of modern vehicles. As vehicle electronics continue to evolve, PCBs will undoubtedly play an increasingly critical role in shaping the future of automotive engineering.