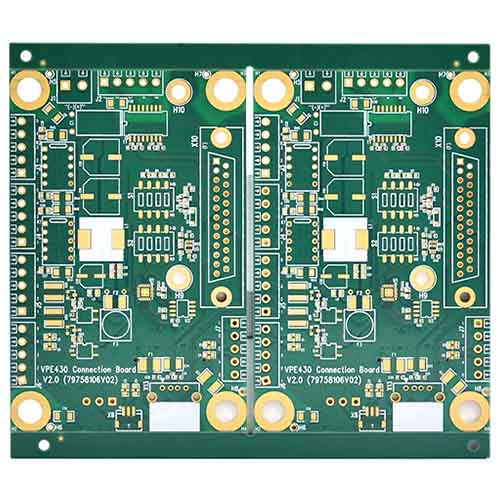

Defining PCB Design and Layout

PCB design and layout encompass the creation of a tangible arrangement for a printed circuit board, facilitating the interconnection of electronic components within a circuit. This intricate process entails orchestrating component placements, mapping out electrical connections, and defining the dimensions and contours of the board. At Wenshu, we offer a comprehensive spectrum of printed circuit board design services, backed by a proficient team specializing in an array of design complexities, from the uncomplicated to the intricate.

Our PCB Design and Layout Offerings

- Schematic Design Developing a visual representation of an electronic circuit through standardized symbols and annotations.

- PCB Layout Design Strategically placing components on the PCB, constructing pathways between them, and optimizing the layout for both performance and manufacturability.

- Library Creation Curating and upkeeping a repository of parts and components for utilization across various PCB designs.

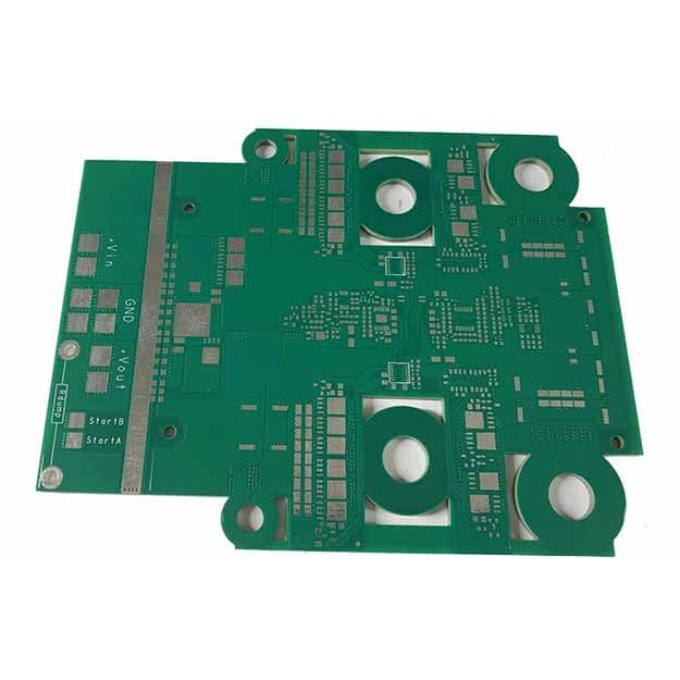

- Design for Manufacturability Identifying potential manufacturing challenges in the design, encompassing factors like component arrangement and trace dimensions.

- Prototype Assembly & Testing Materializing and scrutinizing a prototype of the design to validate its functionality and efficacy.

- Design Review & Enhancement Conducting a meticulous analysis of the design to pinpoint potential shortcomings and avenues for refinement.

Design Expertise

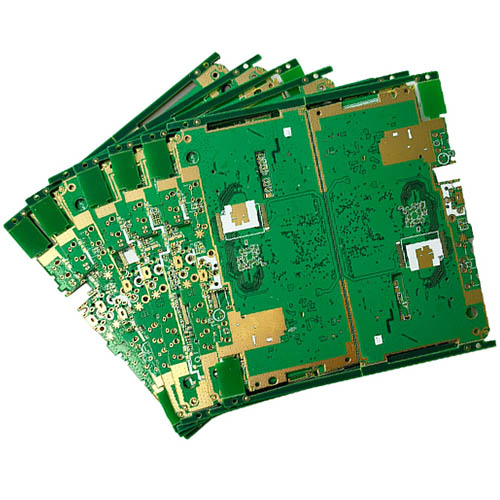

Our proficiency spans an array of design complexities, including but not limited to:

- Single-Sided PCBs

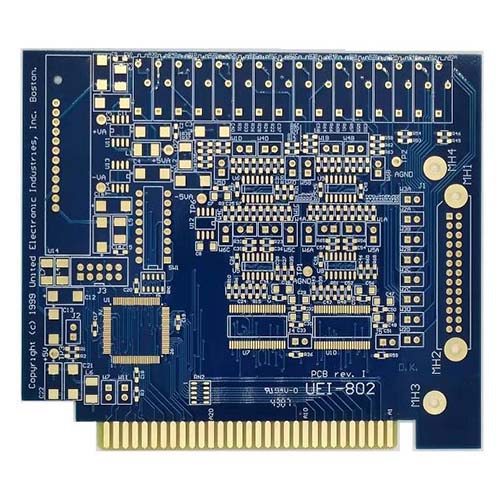

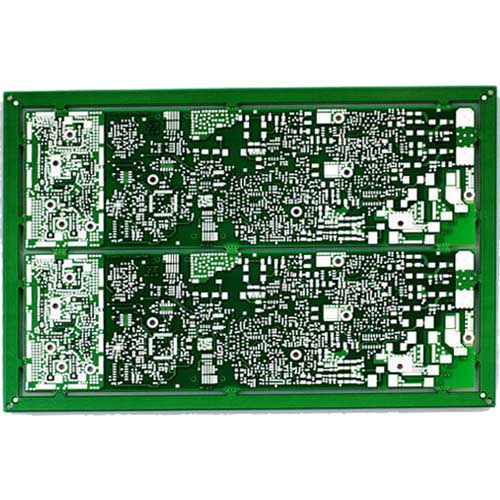

- Double-Sided PCBs

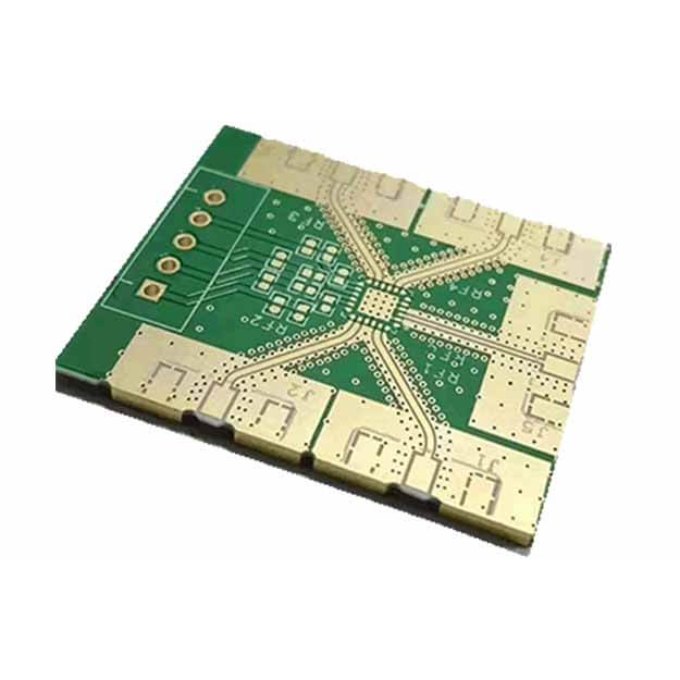

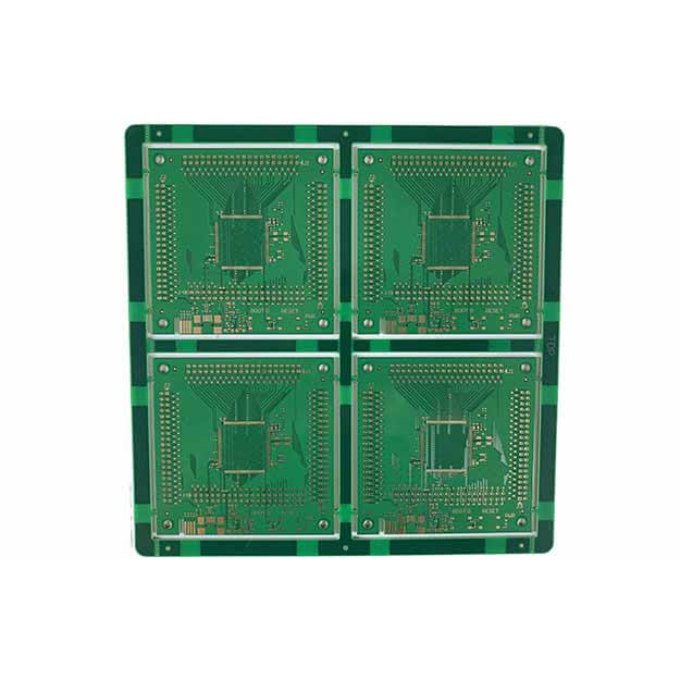

- Multilayer PCBs

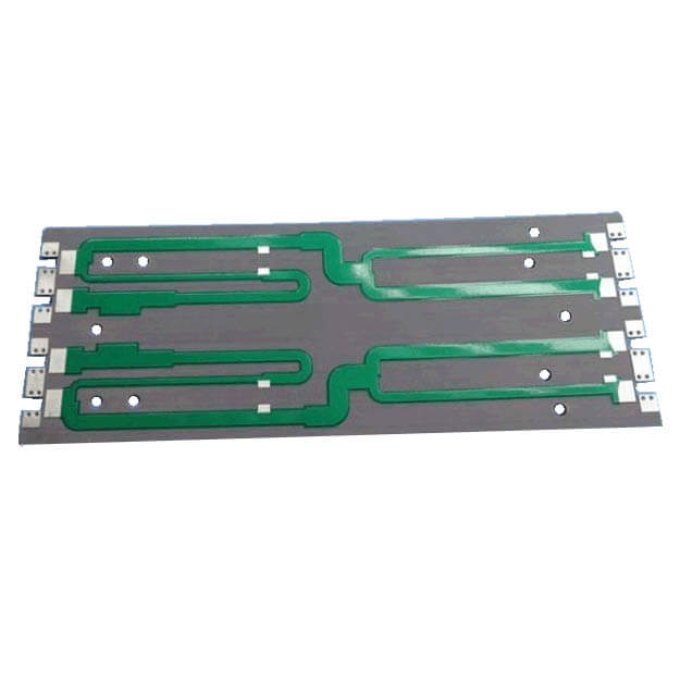

- Aluminum PCBs

- Metal Core PCBs

- Rigid and Flexible PCB Technologies

- Incorporation of Mixed Components (Through-Hole and Surface Mount)