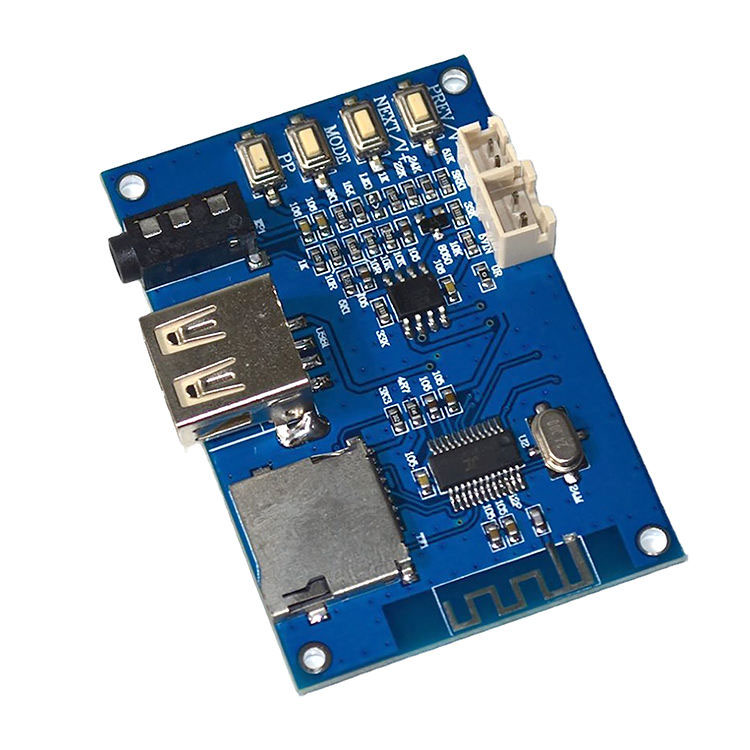

Blue Tooth Pcb Smt Circuit Board Electronic Customized

If you’re looking for a custom Bluetooth PCB (Printed Circuit Board) for surface mount technology (SMT), there are several options available to you.

| Number of Layers | 1 - 40Layers |

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Size | 50*50mm~510*460mm |

| Min Package | 01005 (0.4mm*0.2mm) |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

Prototype to Full Turn-Key Assembly

Through-Hole Lead-Free Wave Soldering

Best Price, Genuine Components

Quality Accreditation ISO9001

-

Description

-

Specification

For those seeking a tailor-made Bluetooth PCB (Printed Circuit Board) using surface mount technology (SMT), a range of possibilities awaits. Here’s a comprehensive look at the steps and considerations integral to obtaining your very own custom Bluetooth PCB:

- Design Phase: Commence by outlining your precise prerequisites for the Bluetooth PCB. Consider the preferred Bluetooth version (e.g., Bluetooth 4.0, 5.0), range, power efficiency, and any required functionalities.

- Schematic and Arrangement: Construct a diagram illustrating the circuit connections and components. Subsequently, fashion the PCB layout, strategically placing components and establishing trace routes based on the schematic. Tools like Altium Designer, Eagle, KiCad, and others can be employed.

- Selecting the Right Manufacturer: Opt for a PCB manufacturer that extends customized services and specializes in SMT assembly. Confirm their proficiency with Bluetooth technology and ability to fulfill your needs.

- Manufacturing the PCB: Furnish the manufacturer with your design files for fabrication. They will create the PCB to your specifications, encompassing layer count, dimensions, and supplementary elements like solder masks and silkscreens.

- Procuring Components: Identify the components imperative for your Bluetooth PCB. You can either supply the components to the manufacturer or allow them to source on your behalf. Assure the compatibility of all components with SMT assembly.

- SMT Assembly: The manufacturer embarks on the SMT assembly process following PCB fabrication. This entails mounting surface-mount components onto the PCB via pick-and-place machines, soldering them utilizing reflow ovens, and conducting meticulous quality control inspections.

- Comprehensive Testing: The PCBs undergo rigorous testing post-assembly to validate adherence to anticipated functionality and performance. This encompasses assessments like functional testing, Bluetooth connectivity checks, and other pertinent evaluations.

- Refinement and Production: If necessary, refine the design and testing phases until achieving the desired outcomes. Once the prototype garners approval, mass production of the Bluetooth PCBs can be initiated.

It’s imperative to remember that the process mentioned above offers a general overview, with particulars subject to variation based on your specifications and the chosen manufacturer. Collaborating closely with the manufacturer during the design and manufacturing stages is pivotal to ensuring your customized Bluetooth PCB meets your expectations.

Check our new product SMT Assembly For Electronic Smart Home

| ltem | Capability |

|---|---|

| Order Quantity | ≥1PC |

| Quality Grade | IPC-A-610 |

| Lead Time | 24 hours expedited service can be offered. 3- 4 days normally for PCBA prototype orders. We will give you an accurate lead time when we quote for you. |

| Size | 50*50mm~510*460mm |

| Board Type | Rigid PCB, Flexible PCB, metal core PCB |

| Min Package | 01005 (0.4mm*0.2mm) |

| Max Package | No limit |

| Mounting Accuracy | ±0.035mm(±0.025mm) Cpk≥1.0 (3σ) |

| Surface Finish | Lead/Lead-free HASL, Immersion gold, OPS, etc. |

| Assembly Types | Surface mount (SMT), Through-hole (DIP), Mixed Technology (SMT & Thru-hole) |

| Component Sourcing | Turnkey (All components sourced by Wenshu), Partial turnkey, Kitted/Consigned |

| BGA Package | BGA Dia. 0.14mm, BGA 0.2mm pitch |

| SMT Parts Presentation | Cut Tape, Partial reel, Reel, Tube, Tray, Laser-cut Stainless Steel |

| Cable Assembly | We supply custom cables, cable assemblies, wiring looms/harnesses and power leads for various industries including automotive, security, mining, medical and entertainment. |

| Stencil | Stencil with or without frame (offered free by Wenshu) |

| Quality Inspection | Visual inspection; AOI checking; BGA placement – X-RAY checking |

| SMT Capacity | 3 Million~4 Million Soldering Pad/day |

| DIP Capacity | 100 Thousand Pins/day |