-

Capability

-

Aluminum PCB Capabilities

| ltem | Capability |

|---|---|

| Material | FR-4 Standard Tg 140°C, FR4-High Tg 170°C |

| Min. Track/Spacing | For External layers: 4oz Cu 10mil/13mil, 5oz Cu 12mil/15mil, 6oz Cu 15mil/15mil For Internal layers: 4oz Cu 8mil/8mil, 5oz Cu 10mil/10mil, 6oz Cu 12mil/12mil |

| Min. Hole Size | 0.15 ~ 0.3mm |

| Max Outer Layer Copper Weight (Finished) | 12oz |

| Max Inner Layer Copper Weight | 12oz |

| Board Thickness | 0.6-6mm |

| Surface Finishing | HASL lead-free, Immersion gold, OSP, Hard Gold, Immersion Silver, Enepig |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green |

| Silkscreen | White, Black |

| Via Process | Tenting Vias, Plugged Vias, Vias not covered |

| Testing | Fly Probe Testing (Free) and A.O.I. testing |

| Build time | 5-15 days |

| Lead time | 2-3 days |

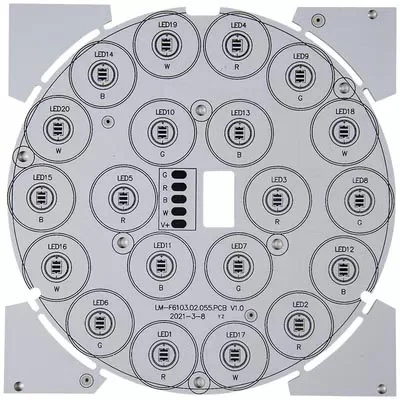

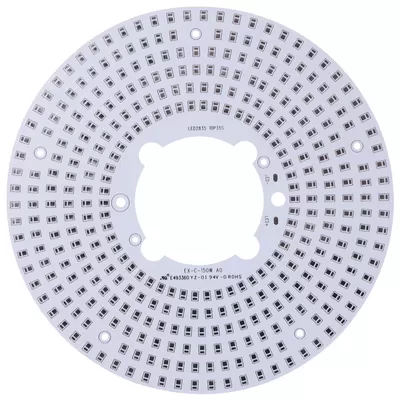

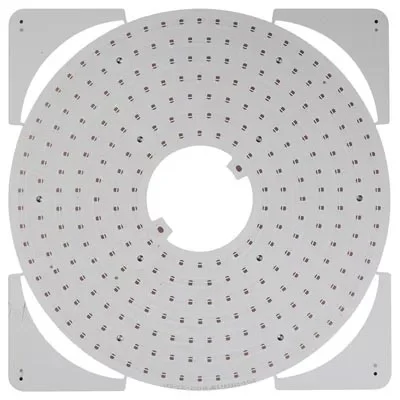

Presenting our cutting-edge Aluminum PCB, meticulously designed to address the exacting demands of electronic applications. These specialized printed circuit boards offer exceptional prowess in thermal management and unwavering durability, rendering them the prime selection for projects necessitating efficient heat dissipation.

Featuring a lightweight yet stalwart aluminum substrate, our Aluminum PCB guarantees steadfast performance across diverse industries. Revel in amplified electrical prowess, design adaptability, and a cost-efficient edge with our PCBs, providing a dependable cornerstone for your electronic blueprints.

Our Aluminum PCBs carve a niche across sectors like automotive, aerospace, LED lighting, and power electronics. Their remarkable thermal management makes them suitable for various electronic devices and systems. Invest in our Aluminum PCBs to unlock the advantages of unparalleled thermal management, unyielding durability, elevated electrical performance, versatile design options, economical efficacy, and flexibility.

Aluminum PCBs, or metal-core or MCPCBs, boast specific capabilities tied to their design and manufacturing methodologies. Here are some prevalent capabilities tied to aluminum PCBs:

- Base Material: Aluminum PCBs rely on aluminum as the core substrate. The aluminum core confers exceptional thermal conductivity and heat dissipation properties, rendering them apt for applications demanding effective heat regulation.

- Layer Count: Aluminum PCBs can be produced with single-sided, double-sided, or multilayer configurations. The layer count hinges on circuit intricacy and application requisites.

- Thermal Conductivity: Renowned for elevated thermal conductivity, aluminum PCBs proficiently dissipate heat generated by electronic components. The base material’s thermal conductivity varies, with higher values preferable for enhanced heat transfer.

- Dielectric Layer: Featuring a dielectric layer wedged between the aluminum core and copper circuit layer, aluminum PCBs assure electrical insulation and uniform heat distribution.

- Copper Thickness: Aluminum PCBs come in diverse copper thicknesses to suit distinct current-carrying capacities and design considerations, often specified in ounces (e.g., 1 oz, 2 oz).

- Surface Finishes: Diverse surface treatments, including Electroless Nickel Immersion Gold (ENIG), HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservatives), and Immersion Tin or Silver, can be employed to safeguard copper traces and enhance solderability.

- Solder Mask and Legend Printing: Solder mask coatings shield copper traces and prevent solder bridges during assembly. Legend printing can also be applied, encompassing component designations and identifying marks.

- Quality Control and Testing: Esteemed aluminum PCB manufacturers institute rigorous quality control procedures to ensure compliance with specifications. Electrical continuity, thermal, and dimensional tests validate the boards’ integrity and performance.

Advantages of Aluminum PCB:

- Optimized Thermal Management: Our Aluminum PCBs excel in heat dissipation due to their remarkably conductive aluminum substrate. They efficiently dissipate heat from components, averting overheating and preserving optimal operating temperatures.

- Durability and Dependability: Fortified by the aluminum substrate, our Aluminum PCBs exhibit resilience against mechanical stress, rendering them robust and dependable even in demanding surroundings. They are less susceptible to vibrations, impacts, and environmental damage.

- Augmented Electrical Performance: Boasting low thermal resistance and elevated thermal conductivity, our Aluminum PCBs proffer heightened electrical efficiency. They curtail power losses and voltage fluctuations, culminating in superior signal integrity and holistic system efficacy.

- Design Versatility: Our Aluminum PCBs can be tailored to your distinct needs. Opt from many sizes, shapes, and layer configurations to harmonize with your project’s unique requisites. Single-sided or double-sided options abound.

- Cost-Efficient Solution: Compared to alternate materials, our Aluminum PCBs offer a remarkable equilibrium of performance and cost-efficiency. They deliver efficient heat dissipation at a compelling price point, conferring substantial value to your investment.